Back to Blog

Gas Detector vs Gas Analyser

What is the difference between a gas detector and gas analyser?

In modern industrial settings, the ability to quickly and accurately detect the presence of harmful gases is extremely important. While some people use the terms gas detectors and gas analysers interchangeably, these two technologies serve distinct purposes and offer unique capabilities and thus should not be confused. Understanding the purposes and benefits of these devices is crucial to ensure the safety of workers, protection of the environment, and the effective operation of a plant.

What is a Gas Detector?

Gas detectors play a crucial role in keeping people safe in industrial work environments. Detecting dangerous gases requires specialist equipment, which means a gas detector is essential anywhere that houses potentially dangerous / explosive chemicals and gases.

Gas detectors are designed to identify the presence of specific gases in the atmosphere and will trigger an immediate alert, such as an alarm and visible notification when concentrations exceed pre-determined levels. They can operate using various sensing technologies, including ultrasonic, electrochemical, or infrared, and are capable of detecting a range of gases, such as toxic, flammable or combustible gases, as well as those that pose an inhalation threat.

This allows workers to swifty evacuate an area and carry out emergency response protocols for the safety of both personnel and equipment.

ATEX certification for gas detectors

ATEX certification is an important European standard for equipment used in potentially explosive environments. Choosing a fixed or portable gas detector that is ATEX certified guarantees it meets safety requirements, thereby preventing explosions and protecting workers' lives in hazardous areas.

Simplicity and reliability

Whether fixed or portable, gas detectors are suitable for use in the most demanding environments, including oil and gas, petrochemical, industrial manufacturing, wastewater treatment, hydrogen, the energy sector and other industries. Modern gas detectors are also ruggedized, meaning they are designed to withstand demanding environmental factors, ensuring consistent and trustworthy readings, even in the most challenging conditions.

Gas detectors are designed to be sufficiently robust to be able to resist environmental and hazardous factors, such as temperature, humidity and pressure, ensuring reliable performance and accurate readings consistently.

Detectors use a range of technologies, such as ultrasonic, electrochemical, or infrared to identify a range of substances, including flammable or combustible gases and those that are hazardous if inhaled.

They give quick, reliable results, making the user aware of, for example explosive atmospheres, oxygen deficiency and toxic gases, which could be fatal.

Although gas detectors ensure that the atmosphere is safe to work in, they do not provide information on the precise concentrations of the gas that is present. This is the role of a gas analyser.

Gas analysers

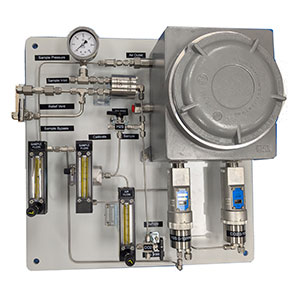

Providing a separate, but complementary role to gas detectors, gas analysers are analytical devices that measure the concentration or quality of a specific gaseous compound within a mixture of gases. Unlike the diffusion-based detection method of gas detectors, gas analysers feature a sensor system that can accurately measure the levels of various gaseous compounds, subjecting them to rigorous analysis. This approach ensures a high degree of accuracy, allowing for the precise quantification of gas types and concentrations.

Just like detectors, gas analysers can be either fixed or portable.

A fixed system would be permanently installed in the plant, regularly providing gas readings. In contrast, portable analysers are usually small, handheld devices that can be carried on-site, allowing the user to have rapid gas analysis data whilst out on site.

This data is invaluable in enabling an in-depth analysis of gases present, contributing to informed decision-making and process optimisation.

Gas analysers are designed to be highly adaptable, catering to a wide range of applications and industries from the oil and gas sector to wastewater treatment plants. They can be configured to monitor the specific gases of concern to suit individual applications.

In addition, gas analysers provide continuous monitoring and data logging capabilities. This allows for the tracking of gas levels over time, enabling the identification of trends and the detection of gradual changes in the atmospheric composition. This information can be crucial for process optimisation, compliance monitoring and long-term risk management.

Optimising safety & efficiency

While gas detectors and gas analysers serve distinct purposes, they often work in tandem to provide a comprehensive safety solution for a plant, personnel and the environment. Gas detectors act as the first line of defence, rapidly alerting workers to immediate threats, while gas analysers offer deeper insights into the gas composition, both enabling informed decision-making and risk mitigation.

Whether a gas detector or gas analyser is needed very much depends on the specific requirements of the project and the operating environment. Factors such as the nature of the gases present, the criticality of the process and the desired level of data transparency all play a role in determining the optimal solution.

By understanding the unique capabilities of gas detectors and gas analysers, industrial businesses can make the right decisions in incorporating these technologies into their operations in order to minimise risks and protect plant and equipment.

Interested in finding out more about gas detectors and gas analysers? Discover more on the links below!